| Materials Used | Types | Uses |

A pressure reducing valve, a popular category of pipe valve, is used widely to reduce pressure in fluid flow, be it steam, air or gas or any kind of liquid. This type of pipe valve is also known as “Pressure Regulator”. It is a kind of throttling device. The pressure reducing valve gives a constant reduced pressure inspite of fluctuations, within reasonable limits and within the inlet pressure, that is the incoming high pressure.

The valves are made of various materials and are available in small, standard, high & super capacity models. They can be installed with required other accessories at places where complete station cannot fit. They are widely used in homes, commercial buildings, and manufacturing plants.

Buying tipsDepending upon the inlet pressure, desired outlet pressure and steam flow rate, pressure reducing valves can be selected and sized. Other factors to consider are:

|

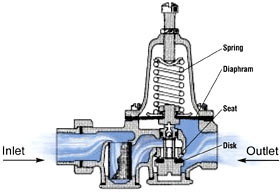

A

pressure reducing valve automatically reduces the pressure from the

water supply main to a lower and a more sensible pressure. When the

water enters the valve from municipal mains, this is constricted within

the valve body and it flows through the inner chamber which is

controlled by an adjustable spring loaded diaphragm and disc. Even if

the pressure of supply water fluctuates, the pressure reducing valve

which is fixed ensures a constant flow of water at a functional

pressure. This continues so long the supply pressure does not drop below

the valve’s pre-set pressure.

A

pressure reducing valve automatically reduces the pressure from the

water supply main to a lower and a more sensible pressure. When the

water enters the valve from municipal mains, this is constricted within

the valve body and it flows through the inner chamber which is

controlled by an adjustable spring loaded diaphragm and disc. Even if

the pressure of supply water fluctuates, the pressure reducing valve

which is fixed ensures a constant flow of water at a functional

pressure. This continues so long the supply pressure does not drop below

the valve’s pre-set pressure. Direct-acting:

This is the most simplest type of pressure relief valve. This type of valve operates with either a flat diaphragm or convoluted

bellows. It is the smallest in size of all the three types and most economical. This type of valve is designed for low to moderate

flows.

Direct-acting:

This is the most simplest type of pressure relief valve. This type of valve operates with either a flat diaphragm or convoluted

bellows. It is the smallest in size of all the three types and most economical. This type of valve is designed for low to moderate

flows. Externally

piloted: In this type of pressure relief valve, the piston operator of the internally piloted design is replaced by double diaphragms replace. This diaphragm can open a large main valve, which in turn allows a greater capacity per line size than the internally piloted pressure relief valve. The diaphragms are also

more sensitive to pressure changes. This type of valve also offers the flexibility to use different types of pilot valves.

Externally

piloted: In this type of pressure relief valve, the piston operator of the internally piloted design is replaced by double diaphragms replace. This diaphragm can open a large main valve, which in turn allows a greater capacity per line size than the internally piloted pressure relief valve. The diaphragms are also

more sensitive to pressure changes. This type of valve also offers the flexibility to use different types of pilot valves.