Threaded Flanges

Threaded flanges are widely demanded as pipe flanges used in different industrial applications. They are the special type of pipe flanges which can be attached to the pipe without welding. Threaded flanges are threaded in the bore which match an external thread on the pipe.

These threads are tapered in order to create a seal between the threaded flange and the pipe as the tapers approach the same diameter. Sometimes a seal weld is also used together with the threaded connection. They are available in various sizes and materials.

Materials used:

- Stainless Steel

- Alloy Steel

- Carbon Steel

- Cast Iron

- Steel

- Aluminum

- Brass

- Bronze

- Monel

- PVC

- Thermoplastic etc.

How

to measure threaded flange?

How

to measure threaded flange?

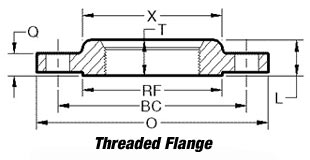

Take the measurements of the following:

- O: Flange Diameter

- Q: Flange Thickness

- X: Hub Diameter at Base

- RF: Raised Face Diameter

- BC: Diameter of bolt circle

- L: Length through hub

- T: Thread Length

Key Features:

- No welding is required.

- Good for small pipe sizes.

- Should be avoided for larger loads, especially when subjected to

higher torque.

Uses of threaded flanges:

Uses of threaded flanges:

- Threaded flanges can be fitted to pipes of various sizes without

welding and this is one chief benefit for which these flanges are

highly demanded.

- They can be used in extremely high pressure applications,

particularly at or near atmospheric temperature, where the necessary

post weld heat treatment is not possible.

- They are ideal for small diameter piping applications.

- They are economical and time saving devices.

- These threaded flanges are normally designed for non-cyclic

applications.

- The flanges are suitable to be used in applications where welding

is hazardous.

- They can be used in highly explosive areas.

The points mentioned below will be a guide for the buyers:

How

to measure threaded flange?

How

to measure threaded flange? Uses of threaded flanges:

Uses of threaded flanges: