Plug Valves

Plug valves are one of the most popular category of pipe vales used in variety of applications. Also known as cock or stop-cock valves, plug valves have been in use since a long period of time. Infact, they were developed for use in citywide Roman plumbing systems and remain as one of the most widely used valves for both on/off and throttling services.

They are a kind of rotational motion valves which are used to stop or start fluid flow. They are so called because of the shape of the disk, which resembles a plug.

Materials used:

- Stainless steel

- Aluminum

- Bronze

- Brass

- Copper

- Nickel

- Cast iron

- Steel

- Plastic

- Rubber etc.

Buying TipsCertain features to look for are as follows:

- Body Options

- Port Options

- End Connections

- Sizes

- Material of construction

- Types

- Durability

- Corrosion resistant

|

Types of Plug Valves:

Plug valves are made with tapered and cylindrical plugs and are

available in various types like given below:

- Nonlubricated plug valve: This is the earliest form of

plug valve. A nonlubricated plug valve may use a tapered plug having

a mechanical lifting device, which unseats the plug before it is

turned to reduce the operating torque required. It may also have an

elastomeric sleeve or plug coating with a low coefficient of rubbing

friction. Though this design is still in use, the problems with

galling and sticking limit their usefulness.

- Lubricated plug valve: The lubricated plug valves were

developed to overcome the difficulties of non-lubricated plug

valves. In this type of plug valve, the lubricant is forced into the

valve under pressure. The lubricant prevents leakage between the

plug and body. The lubricant also reduces friction and wear between

the surfaces when the plug is turned. The use of lubricant between

the plug face and the seat eliminates most of the problems of

nonlubricated valves.

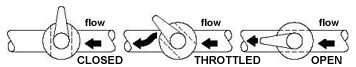

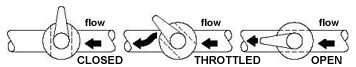

- 2-port valve: This kind of plug valve has two positions—one

which is open to allow flow, and the other to shut or close to stop

flow. Ports are openings through which fluid can enter or leave in

the valve body.

- 3-way plug valve: In this type of plug valve, there are

three ports and flow from one port could be directed to either the

second or third port. A 3-way plug valve can also be designed in

such a way to shift flow between ports 1 and 2, 2 and 3, or 1 and 3.

They can also connect all three ports together.

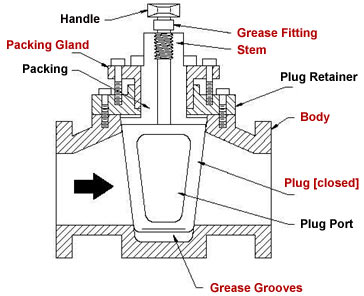

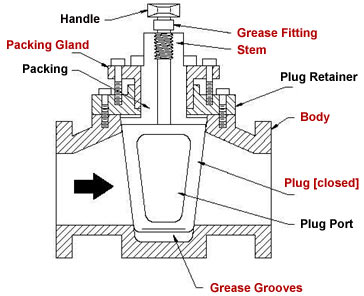

Parts of plug valves:

The body of the plug valve comprises three parts:

The plug is a cylindrical, tapered or cone-shape mechanism that can

raise or lower within the seat to restrict, maintain or completely shut

off flow. The plug valve is opened by rotation and the plug is the only

element that is capable of movement.

A diagrammatic representation of plug valve is given below.

The body of a plug valve is designed to receive the tapered or

cylindrical plug.

Uses of plug valves:

Uses of plug valves:

- Plug valves are high capacity valves that are found widely in-

- low-pressure sanitary applications and

- industrial applications, like petroleum pipelines, chemical

processing and related fields, and power plants.

- They are extremely versatile valves that can be used for

directional flow control.

- They can be used even in moderate vacuum systems.

- Plug valves can efficiently handle gas and liquid fuel.

- They can safely handle extreme temperature flow, such as boiler

feed water, condensate, and other such elements.

- Plug valves can be used to regulate the flow of liquids

containing suspended solids, for example, slurries.

Industries Using Plug Valves:

- Air Conveying

- Automobile plants

- Atomic Energy Installations

- Bakeries

- Chemical industry

- Dairies

- Fertilizer plants

- Iron and steel industry

- Testing laboratories etc.

The points mentioned below will be a guide for the buyers:

The body of the plug valve comprises three parts:

The body of the plug valve comprises three parts: