Pipe Needle Valves

A pipe needle valve is widely used as a pipe valve in various pipe fittings. It is a type of pipe valve which is used to make relatively fine adjustments in the amount of fluid flow. This valve is used widely because of its excellent control of flow. With a small orifice and a threaded, needle-like plunger, a needle valve allows precise regulation of flow.

It is used in almost all types of industrial applications. It is widely used to accurately regulate the flow of liquids/fluids/gases at low flow rates. This valve allows for precise resistance to flow. The valve is similar in design and operation like globe valve. However, instead of a disk in globe valve, a needle valve has a long tapered point at the end of the valve stem.

Materials

used:

Materials

used:

- Aluminum

- Brass

- Bronze

- Copper

- Stainless steel

- Nickel

- Cast Iron

- Rubber

- Plastic

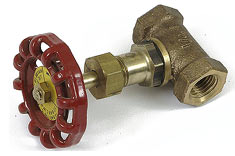

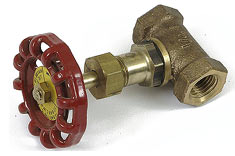

Parts of a needle valve:

As seen in the figure, the parts of a needle valve consists of:

- Handwheel

- Stem

- Bonnet

- Packing

- Body &

- Stem Point

Construction of a needle valve:

The distinguishing feature of a needle valve is the existence of a long, tapered, needle- like point on the end of the valve stem. This acts as a disk. The longer portion of the needle is small in size than the orifice in the valve seat. It passes through the orifice before the needle seats. This arrangement allows a very gradual increase or decrease in the size of the opening.

How does a needle valve operates?

As the needle-shaped screw is turned and the plunger retracted, flow between the seat and the plunger takes place. However, here until the plunger is completely retracted, the flow of the fluid is significantly impeded. Since it takes many turns of the fine-threaded needle screw to retract the plunger, precise regulation of the flow rate is possible.

Uses & Applications of needle valves:

- Suited for aggressive and high purity chemicals.

- Used in flow metering applications.

- Used when a constant, calibrated, low flow rate must be maintained for a period of time.

- Needle valves are usually easy to shut off completely, with just a finger tight pressure.

- In hot water heating applications, small and simple needle valves are used as bleed valves.

- Needle valves are applied in situations where the flow must be gradually brought to a halt.

- They are also used where precise adjustments of flow are necessary or where a small flow rate is desired.

- Needle valves are used as both on/off valves and for throttling service.

- Different construction materials make needle valves suitable in situations where corrosion, high or low temperatures or extensive wear are possible.

- Needle valves are used in every industry in an incredibly wide range of applications.

- They are found in every industry from aerospace to zoological sciences.

- They are used in every service from gas and liquid dispensation to instrumentation control and cooling to power generation.

The points mentioned below will be a guide for the buyers:

Materials

used:

Materials

used: