Check Valves

Check Valve a popular type of pipe valve are used to prevent flow reversal in piping systems. Check valves are appropriate for service in horizontal or vertical piping tuns. In other words, check valve is a mechanical device that allows fluid to flow through it in only one direction.

Check valves consist of two-port valves. This means that they have two openings in the body, one for fluid to enter and the other for fluid to leave. That is why they are classified as “one-directional valves”. They are available in various designs, sizes and materials and used in a wide variety of applications.

Materials

used:

- Stainless steel

- Titanium

- Brass

- Alloy

- Carbon steel

- Cast iron

- Aluminum

- Brass

- Bronze etc.

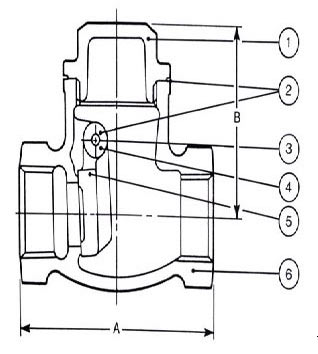

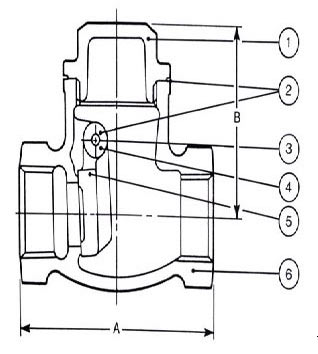

Parts of a check valve:

PART:1 Cover |

PART:2 Gasket |

PART:3 Pin |

PART:4 Nut |

PART:5 Disc |

PART:6 Body |

Types of Check Valves:

Horizontal Swing Check ValveOperates in the horizontal

position.

|

Piston Check ValveWorks up and down providing a very

strong, firm seal under high pressure conditions.

|

Ball Check ValveUses a ball rather than a clapper.

|

Working of a check valve:

There is a hinged ball or door which is placed inside the valve. With

the pressure coming upstream the ball is held open. On the other hand,

when the pressure increases on the downstream side, it forces the ball

or door to close which stops any back flow. An important factor in check

valves is the cracking pressure. This is the minimum upstream pressure

at which the valve will operate. Typically the check valve is designed

in such a way to specify a specific cracking pressure.

Uses of check valve:

- Check valves are best suited for moderate velocity applications.

- They are often part of common household items.

- They work automatically.

- They do not have any valve handle or stem.

- They are self-activating safety valves.

- They permit gases and liquids to flow in only one direction.

- They prevent liquid flow from reversing.

- They are used in many fluid systems like in chemical and power

plants, and in many other industrial processes.

- They are capable of mixing multiple gases into one gas stream.

- Check valves are installed in irrigation sprinklers and drip

irrigation emitters to keep the lines from draining when the system

is shut off.

The points mentioned below will be a guide for the buyers: