Ball Valves

A ball valve is a type of pipe vale that opens by turning a handle attached to a ball inside the valve. They are used for quick shut off and low emission application. They are durable and can work to achieve perfect shutoff or closure even after years of not-in- use. They are always an excellent choice for shutoff applications.

They are sometimes preferred to globe valves and gate valves for this purpose. Although, ball valves cannot offer the fine control that may be required in throttling applications but are still sometimes used for this purpose.

Materials used:

- Brass

- Copper

- Cast Iron

- Bronze

- Ductile iron

- Stainless steel

- Metal alloys

- Plastic

- Ceramic etc.

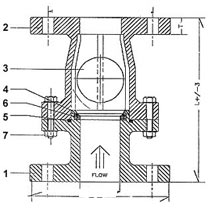

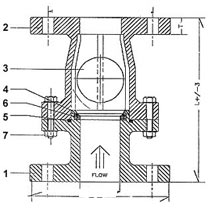

Parts of ball valves:

- End piece

- Body

- Ball

- Cover ring

- Body seals

- Seats

- Bolt & nuts

Styles of ball valves:

Ball valves have three general body styles. They are as follows:

- Split body

- One-piece

- Two-piece

- Three-piece

- Flanged body

- Top entry

- Welded

Each of these body styles have specific advantages depending upon

the requirements of the given application.

Types of ball valves:

There are three general types of ball valves:

- Full port: This has an over sized ball so that the hole

in the ball is of the same size as the pipeline thereby resulting in

lower friction loss. The valve is larger and the flow is

unrestricted.

- Standard port: This has a smaller ball and hence a

smaller port. This is less expensive. Flow through this type of

butterfly valve is one pipe size smaller than the valve's pipe size

which results in slightly restricted flow.

- Reduced port: Here the flow through the valve is two pipe

sizes smaller than the valve's pipe size which also results in

restricted flow.

Salient features of ball valve:

Buying tips

Options of ball valves:Ball valves are manufactured with a

number of options to meet the demands of a variety of applications:

- Actuators: Ball valves are suitable for

automation which is accomplished by using either an

pneumatically or an electrically actuator. The actuator is

connected to the ball valve with the help of a linkage kit.

- Firesafe: It is essential that the ball

valves used in gas and oil pipeline applications are firesafe.

It is considered firesafe if, when exposed to fire, it will

continue to provide minimal leakage through the seat and stem.

Other factors to consider:

- Design standards

- Face to face dimension

- Material of construction

- Size range

- Pressure rating

- Design

- Ends etc.

|

Ball valves have certain characteristics which make them superior to

other valves. They are as follows:

- Positive shut off

- Quick in action

- No lubrication

- Visual on/off indication

- Compact design

- Longer life

- Corrosion resistant

- Low pressure drop

- Simplicity

Uses of ball valves:

The various uses of ball valves are as follows:

- They are used in situations where tight shut-off is required.

- They are wide duty pipe valves.

- They are able to transfer liquids with suspended solids

(slurries), gases, liquids.

- They provide superior ease of operation.

- They can maintain and regulate high volume, high pressure and

high temperature flow.

- The ball valve body design permits inspection as well as repair

of seats and seals without removing the valves’ body from the

line.

- Firesafe ball valves provide effective shut-off during or

following a fire or when exposed to excessive temperatures.

- Ball valves are used in gas and oil pipelines.

The points mentioned below will be a guide for the buyers:

There are three general types of ball valves:

There are three general types of ball valves: